Corrosion to Metals Test

By: Kate Hatherley, C.TECH., LABORATORY TECHNICAL SPECIALIST, email

The method reviewed here is UN TDG Part III Rev. 6 Test Methods for Corrosion to Metals Section 37.4. It is one of the corrosion tests performed inside Dell Tech’s ISO 17025 accredited laboratory. Our corrosion testing capabilities also include a method for corrosion to skin. For more information on that method, jump to this page about Corrositex®.

In this article, we review our corrosion testing services, including how we conduct the test. First, let’s take a look at the purpose of metal corrosion testing.

Why do you need a metal corrosion test?

Your product may need corrosion testing to determine if your product is corrosive to metals. The purpose is to classify the product for shipping and GHS classification.

Test results will determine if your product is considered corrosive to metals for the purpose of shipping, Safety Data Sheet (SDS) classification, and provide proof of classification for Transportation of Dangerous Goods (TDG).

This applies to consumer or workplace chemicals that are liquid or solid products that may become liquid during transport, with a high or low pH, or containing ingredients known to be corrosive to metals.

Consumer product examples include general cleaners, washer or dishwasher cleaners, sink drain and disposal cleaners, descalers, and disinfectants containing peroxide.

Workplace product examples include but are not limited to, general cleaners and descalers, manufacturing process wastes, and disinfectants.

Corrosion to metals Test C1 is designed to assess the corrosion hazard for an appropriate classification of a liquid and solids that may become liquid as a substance corrosive to metals. If a sample is determined corrosive to metals through this test, the product will be classified as packing group III for shipping and Corrosive to Metals – Category 1 for GHS. This particular test is required by Transport Canada for classification under the Transportation of Dangerous Goods (TDG) regulations and the US Department of Transportation (DOT) under the Federal Motor Carrier Safety Administration (FMCSA) in the USA.

In 2014 the Transportation of Dangerous Goods Regulations Part 2 was amended to require a Consignor (the shipper) of dangerous goods to have available a Proof of Classification document for 5 years after the date of shipment.

Proof of Classification may be a test report, a lab report, or a document that explains how the dangerous good was classified. Proof of Classification must include the date of classification, the technical name of the dangerous good, classification of dangerous goods, and the method of classification under TDG part 2 of Chapter 2 of the UN TDG recommendations.

How do we conduct our metal corrosion test?

UN TDG Part III Rev. 6 Test Methods for Corrosion to Metals Section 37.4 describes in detail the procedure and how to evaluate the results.

Three mild steel specimens of SAE 1020 steel and three 7075-T6 non-clad Aluminum (with 120 grit finish) specimens are subjected to the test sample.

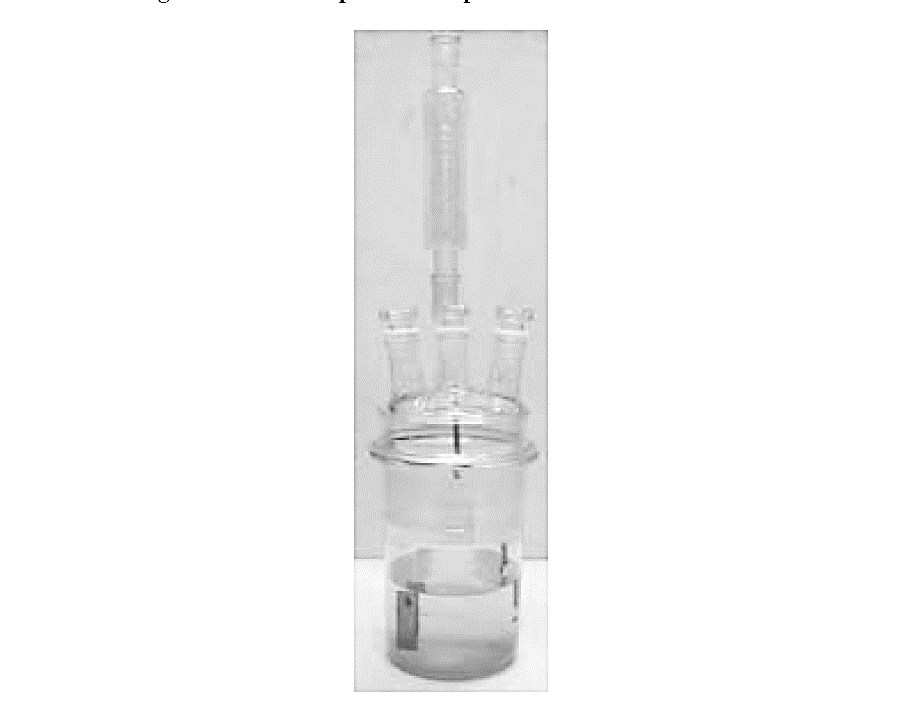

Using a reaction vessel with four-neck molded reaction vessel cover and condenser, one metal test specimen is immersed completely in the solution at least 10 mm below the surface, one is immersed halfway in the test solution and half in the vapour phase, and one is suspended completely within the vapour phase.

The substance being classified shall have a minimum volume of 1.5 L to ensure enough reactive agent during the whole exposure time. The metal specimens shall be exposed to the test solution at 55°C ± 1 for at least one week (168 ± 1 hour).

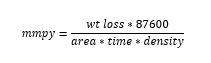

The corrosion rate expressed as millimeters per year (mmpy) is calculated as follow:

Where:

- Wt loss = weight loss is in time (g),

- Area = area of metal surface exposed (cm2),

- Time = number of hours that the metal was exposed and

- Density = metal density (g/cm2).

A mixture or substance is classified as corrosive for shipping and GHS classification purposes if it has a corrosion rate on steel or aluminum surfaces, greater than 6.25 mm per year at a test temperature of 55°C, on any of the three test coupons; fully immersed, partially immersed or vapour phase.

The removal of the corrosion to metals packing group III/category 1 can help you save money on packaging and shipping fees as well as make it easier to market your product to potential buyers.

Need any more support with your metal corrosion testing?

Dell Tech Laboratories is equipped and the staff are trained to perform the UN TDG Part III Rev. 6 Section 37.4 – Test method for corrosion to metals. Our lab is ISO 17025 accredited. We can help you test and classify your products for shipping, GHS, CCCR, or CPSC.

Dell Tech can also consult on the following:

- Shipping for TDG/DOT

- GHS requirements in Canada or the USA

- Choosing the appropriate test method to classify your product appropriately