Floor and Wall Cleaner Products Testing: ASTM D4488-A5

By: Katherine Hatherley, Lab Technician, email

What Products: Floor cleaners, wall cleaners, hard-surface cleaners, multi-surface cleaners, multi-purpose cleaners.

What Test: ASTM D4488-A5 – Standard Guide for Testing Cleaning Performance of Products Intended for Use on Resilient Flooring and Washable Walls.

Why This Test: This test is used to determine a product’s cleaning efficiency by its ability to remove standard soils from a standard test substrate.

Results: The results may be used for claims substantiation, performance comparison to other products and proof of performance for EPA Safer Choice®, Green Seal® and UL ECOLOGO® certification programs.

Performance testing is used to determine how well a cleaning product works, on its own or compared to the competition. Manufacturers that want to put a claim on their label, such as ‘twice the cleaning power of Competitor XYZ’ will do performance testing to validate this claim. Performance testing is also used during product development to determine which potential formulation is superior. If you have an all-purpose cleaner or a floor cleaner, Dell Tech can analyze your product with an international testing standard to determine how well it works.

ASTM D4488-A5 is a standard method for testing the cleaning performance of products intended to be used on resilient flooring and washable walls that is recognized worldwide. This is applicable to all multi-purpose household cleaners and may also apply to some industrial/institutional cleaners.

How does the test work?

A specific soil and substrate combination are prescribed by the method. In the case of method A5, white vinyl tiles are used, and the soil has two component parts: a particulate soil, and an oil blend soil.

The particulate soil portion is a combination of 10 constituents first mixed by hand, but then transferred to a ball mill to be mixed for 18 hours. After this, the mixture must be dried in a tray at either room temperature or an oven with occasional turning. But we’re not done yet! Once dry, the particulate soil must be pulverized and filtered through a mesh screen. This lengthy process is why we lovingly refer to our soils as “artisanal soils” at Dell Tech.

The oily blend soil consists of 9 ingredients prepared over a steam bath.

A crucial step in this test is the consistent application of the soil to the vinyl. A template frame is used to contain the soil in the middle area of the tile. A precise amount of 50mg of the particulate soil is placed within the frame. A paper towel cut to the exact size is wet with 5 drops of the oily blend soil and placed over the particulate soil for 10 seconds. After this, the operator must take care to not use too much pressure while spreading the soil within the framed area on the tile. Too much pressure during the application of the soil may alter the results of the test. The tiles must be air-dried for 24 hours.

After all of this preparation, the cleaning test is performed using a washability apparatus.

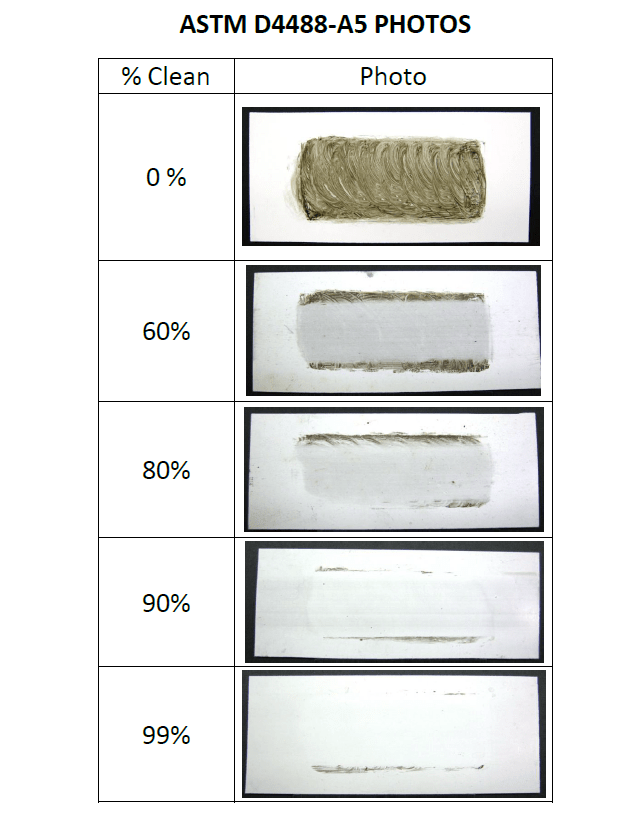

But how is the cleaning efficacy of the product evaluated?

Reflectance readings are taken of the vinyl tiles before soil application, after soil application, and finally after cleaning, using a colorimeter. These values are used to determine the overall cleaning efficiency of a product intended for use on resilient flooring and washable walls. It should be noted that this test excludes “windows, mirrors, carpets, ceramic tiles, and laminated countertops”.

We perform this test method right here at Dell Tech. If you have any questions regarding this test, or would like to have us evaluate your product for you, please contact us.

For more information on performance testing, check out our other presentations on SlideShare & YouTube.

Dell Tech SlideShare Presentations

Contact:

Dell Tech

Joe McCarthy, Senior Regulatory Affairs Specialist

jmccarthy@delltech.com

519-858-5024

Dell Tech has provided professional, confidential consulting services to the chemical specialty

industry in Canada, the USA, Europe, and Asia for the last 40 years.

Contact us today for more information.

www.delltech.com

Good afternoon

I am trying to locate the latest SDS (safety data sheet) for your product ASTM D4488-A5 Oil Blend