Navigating Laundry Detergent Regulations and Testing Methods: A Comparison between Canada and the U.S.

By: Ivy Tang, PRINCIPAL REGULATORY CONSULTANT, email and Farah El Saad, JUNIOR LABORATORY TECHNICIAN, email

Introduction

Laundry detergent regulations are more than just bureaucratic red tape—they’re vital to ensuring consumer safety, environmental protection, and product effectiveness. However, the current regulations can differ significantly between countries, impacting how products are developed, tested, and marketed. In this blog post, we’ll dive into the key differences between Canadian and US laundry detergent regulations, explore essential testing methods, and discuss why compliance with these standards is crucial for manufacturers.

Table of Contents

- Understanding Laundry Detergent Regulations in Canada and the U.S.

- Canadian Regulations for Laundry Detergents

- US Regulations for Laundry Detergents

- Comparing Canadian and US Regulations

- Key Performance Testing Methods and Third Party Certifications for Laundry Detergents

- The Importance of Testing in Regulatory Compliance

- How Dell Tech Can Help

- Regulatory Support

- In-house Laundry Detergent Testing

Understanding Laundry Detergent Regulations in Canada and the U.S.

Canadian and U.S. regulations apply to various types of laundry detergents, including powder laundry detergent, laundry soap, detergent sheets, pod detergents (such as Tide Pods), and stain removers.

Canadian Regulations for Laundry Detergents

The following is a list of regulations that applies to laundry detergents sold in Canada. To learn additional information about Canadian requirements, read our blog Canadian Laundry Detergent Regulations blog post.

- Consumer Chemicals and Containers Regulations (CCCR): Governs the classification, packaging, and labeling of laundry detergents, requiring hazard symbols and bilingual warnings. Packaging must be durable and child-resistant if needed. The CCCR also restricts certain toxic substances and limits chemical concentrations.

- VOC Regulations: Limits the maximum concentration of volatile organic compounds (VOCs) in laundry products to reduce air pollution. Products must be reformulated to meet these limits, which are enforced to prevent smog and ozone formation.

- Canadian Environmental Protection Act (CEPA): Requires that all chemicals in laundry detergents be listed on the Domestic Substances List (DSL) or Non-Domestic Substances List (NDSL). Chemicals on the NDSL face import restrictions and tracking requirements.

- Hazardous Products Regulations (HPR): Applies to industrial and workplace use, mandating proper labeling and Safety Data Sheets (SDS) for hazardous components. Compliance is overseen by Health Canada and includes adherence to the Workplace Hazardous Materials Information System (WHMIS).

- 2-Butoxyethanol Regulations: Limits the concentration of 2-butoxyethanol (2-BE) in laundry stain removers to 22% (w/w) due to health concerns. Concentrations must be verified by accredited laboratories.

Read about Canadian Regulations for Laundry Products to learn more.

U.S. Regulations for Laundry Detergents

The following is an overview of the regulations for laundry detergents sold in the U.S. For more details on U.S. requirements, check out our blog post on U.S. Laundry Detergent Regulations.

- Federal Hazardous Substances Act (FHSA): Regulates labeling and safety, requiring hazard warnings and safe handling instructions. Products with certain chemicals may need child-resistant packaging, overseen by the Consumer Product Safety Commission (CPSC).

- California Cleaning Products Right to Know Act: Mandates clear ingredient disclosure on labels and websites for products sold in California, including those on Prop 65 and EU fragrance allergen lists, enhancing transparency.

- EPA Safer Choice Program: Certifies products with less harmful chemical formulations, ensuring they meet safety and performance criteria while promoting environmental friendliness.

- Federal Trade Commission (FTC) Guidelines: Ensures accurate advertising claims, including performance and environmental benefits, and requires genuine endorsements and disclosures.

- Occupational Safety and Health Administration (OSHA): Requires detailed Safety Data Sheets (SDS) and labels for industrial detergents, along with employee training and protective measures to ensure workplace safety.

Read U.S. Regulations for Laundry Detergents to learn more.

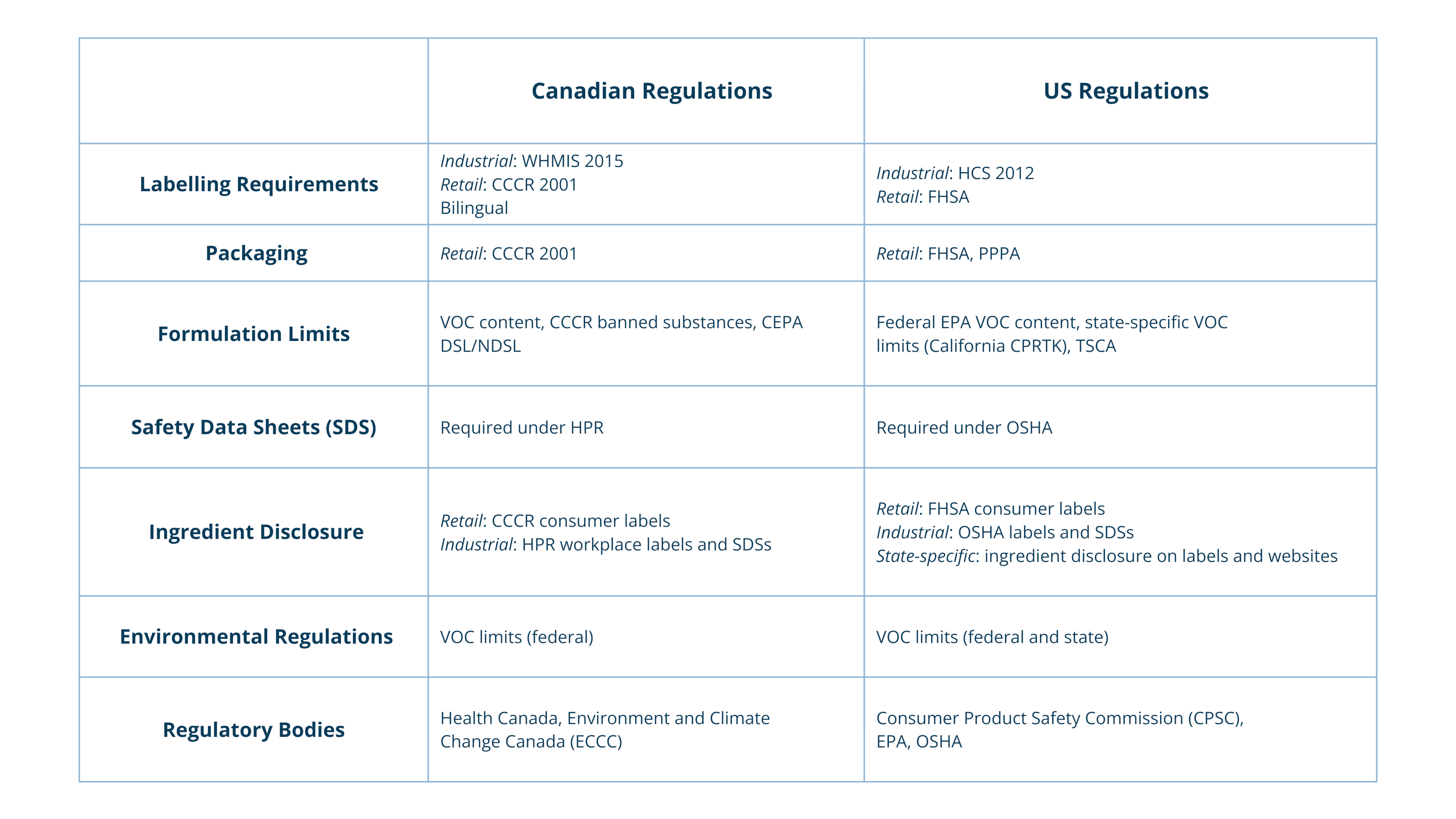

Comparing Canadian and US Regulations

Whether a laundry detergent is manufactured, sold, or used in an industrial or commercial setting, both Canada and the US have regulations in place to ensure the safety of human health and the environment. The table below highlights the differences and similarities between regulations in both countries and outlines the requirements for market entry.

Key Performance Testing Methods and Third-Party Certifications for Laundry Detergents

To assess product performance and substantiate claims, the following test methods are recommended:

- ASTM D4265 (Standard Guide for Evaluating Stain Removal Performance in Home Laundering): This standard provides guidelines for evaluating the stain removal performance of laundry detergents under home laundering conditions. It is essential for ensuring that products fulfill their stain removal claims, which is crucial for consumer satisfaction. In this method, fabric stains are artificially applied to specific fabric types, such as 100% cotton or polycotton, and allowed to set for a specified period. The stained swatches are then washed with the detergents being compared using a colorimeter, and the effectiveness of stain removal is assessed.

- DCC-11: Prewash Spotter Stain Remover – HCPA Method: Developed by the Household & Commercial Products Association (HCPA), this method is widely recognized in both Canada and the U.S. It evaluates the effectiveness of spot treatments before full washing cycles in home laundering conditions. The standardized procedure involves four key steps: (1) Stain Application, (2) Treatment with Pre-Wash Spotter, (3) Laundering, and (4) Stain Removal Evaluation. This method assesses how well pre-wash spotters remove various stains commonly encountered in household settings.

Widely recognized certification programs and international ecolabelling schemes include:

- Green Seal is a designation awarded to products and services that meet rigorous environmental and performance standards set by Green Seal, a nonprofit organization. Green Seal GS-48 and GS-51 specify performance, environmental, and health requirements for household and industrial laundry products respectively. Green Seal certification is recognized internationally, making them valuable for products that aim to meet global standards.

- EPA Safer Choice Certification guarantees that products are free from hazardous chemicals, advocates for safer alternatives, and supports sustainability. Through clear labeling and rigorous standards, the certification reduces exposure to toxic substances, enhances public health, and encourages environmentally responsible practices.

- HE (High Efficiency) certification for laundry detergents signifies that the product is designed to work effectively in high-efficiency washing machines. These detergents are formulated to produce fewer suds and work well in low water settings, which are characteristic of HE machines. HE certification ensures that the detergent meets specific standards for performance and sudsing, optimizing its cleaning power while reducing water and energy usage. This certification helps consumers choose detergents that are compatible with HE washers, promoting efficient washing and lower environmental impact.

- UL ECOLOGO Certification: A globally recognized environmental certification awarded to products that meet rigorous sustainability and performance standards. EcoLogo certifies laundry products based on their reduced environmental impact throughout their lifecycle, including factors like resource use, emissions, and waste. This certification helps consumers and businesses identify environmentally responsible products, supporting sustainable choices by ensuring that certified items are both effective and have a lower environmental footprint.

Other test methods commonly performed prior to market entry:

- Stain Removal, Color Fastness, and Foaming Tests: These tests are fundamental in determining the overall effectiveness and quality of laundry detergents. Stain removal tests (e.g. ASTM D4265) assess a detergent’s ability to remove various types of stains, while color fastness tests (e.g. AATCC Test Method 61) ensure that fabrics retain their color after multiple washes. Foaming tests (e.g. ASTM D1173) measure the amount and stability of foam produced, which can influence consumer perception of cleaning power.

- Detergent Stability: Evaluates how well a laundry detergent maintains its quality over time under various conditions, such as temperature fluctuations, humidity, and light exposure. This test ensures that the detergent remains effective and safe throughout its shelf life, minimizing the risk of degradation or performance issues.

- Skin Sensitivity and Irritation: Tests are designed to determine whether the detergent causes any skin irritation or allergic reactions. This is crucial for guaranteeing that the detergent is safe for use on clothing that comes into contact with the skin, thereby protecting users from potential allergic reactions or discomfort.

- pH Level Testing: Measures the pH of the detergent solution to ensure it falls within a safe range for both fabrics and skin. By maintaining a balanced pH, this test helps prevent damage to clothing and avoids skin irritation, ensuring the detergent is gentle yet effective.

- Biodegradability: Assesses how quickly and completely the detergent breaks down in the environment. This test promotes environmental responsibility by ensuring that the detergent does not contribute to long-term pollution and is more eco-friendly, aligning with sustainability goals.

- Rinsability : Examines how easily the detergent rinses out of fabrics. Effective rinsability prevents residue build-up on clothing, ensuring that fabrics are clean and free from leftover detergent, which could otherwise cause irritation or affect the fabric’s texture.

- Water Hardness Compatibility: Determines how well the detergent performs in various levels of water hardness. This test ensures effective cleaning across different water conditions, reducing issues like soap scum and ensuring consistent performance in areas with hard water.

- Environmental Impact Testing: Evaluates the overall effect of the detergent on the environment. Key aspects include aquatic toxicity (impact on aquatic organisms), biodegradability (product break down in the environment), and environmental footprint (resource use, emissions, and overall impact throughout product lifecycle). These tests help assess the detergent’s ecological impact, ensuring it has minimal negative effects on aquatic life and the broader environment.

The Importance of Testing in Regulatory Compliance

Why Testing is Essential

Testing is critical for several reasons. First, it ensures consumer safety by verifying that products are free from harmful substances and are safe to use. Second, it guarantees performance, ensuring that products meet the claims made by manufacturers, such as stain removal efficacy and color protection. Lastly, testing is crucial for regulatory compliance, helping manufacturers meet the legal requirements in both Canada and the U.S. For instance, liquid laundry detergent is often tested for its effectiveness in removing stains, catering to sensitive skin, and offering hypoallergenic options, ensuring it is both safe and effective.

Conclusion

Navigating laundry detergent regulations in Canada and the U.S. reveals differences and similarities in their approaches to safety and environmental protection. In Canada, the Consumer Chemicals and Containers Regulations (CCCR), VOC regulations, and the Canadian Environmental Protection Act (CEPA) govern product safety, labeling, and environmental impact.

In the U.S., the Federal Hazardous Substances Act (FHSA) ensures similar safety measures, while additional regulations like the California Cleaning Products Right to Know Act require detailed ingredient disclosure at the State level. The Environmental Protection Agency (EPA) manages VOC limits and safety through the Safer Choice Program, while OSHA enforces safety information and employee training.

Both countries emphasize clear labeling, child-resistant packaging, and rigorous testing. Common testing methods, such as ASTM D4265 for stain removal, VOC content analysis, and environmental impact assessments, are essential for ensuring product effectiveness and safety. Understanding these regulations helps manufacturers meet high standards and successfully navigate the North US market.

Key Takeaways

- Regulatory Landscape: Both Canada and the U.S. have rigorous regulations governing laundry detergents, focusing on safety, environmental impact, and product efficacy. In Canada, regulations like the CCCR, VOC limits, and CEPA play crucial roles, while in the U.S., the FHSA, California Cleaning Products Right to Know Act, and EPA Safer Choice Program set standards.

- Labelling and Packaging: Clear labeling, including hazard warnings and ingredient disclosure, is mandatory in both countries. Canada requires bilingual labels and specific hazard symbols, while the U.S. mandates compliance with the Poison Prevention Packaging Act and the California Right to Know Act.

- Performance Testing: Essential testing methods include ASTM D4265 for stain removal, VOC content analysis, and environmental impact assessments. These tests ensure that products perform as claimed and meet safety and environmental standards.

- Certification Programs: Certifications such as Green Seal, EPA Safer Choice, and UL ECOLOGO help products stand out by meeting stringent environmental and performance criteria, benefiting both manufacturers and consumers.

- Regulatory Compliance: Adhering to these regulations and standards is crucial for market entry and success. Effective testing and certification not only ensure regulatory compliance but also enhance product safety and performance.

How Dell Tech Helps

Regulatory Support

Ensure your laundry detergents meet regulatory standards with Dell Tech’s expert support. We offer consulting for Canadian and U.S. markets, covering CCCR, VOC, CEPA, FHSA, and California Cleaning Products Right to Know Act.

We handle documentation, testing, and compliance audits for certifications like UL ECOLOGO, Green Seal, and EPA Safer Choice. Partner with us to streamline your compliance and stay updated on regulatory changes. Visit our website or contact us to learn more.

In-house Laundry Detergent Testing

Elevate your laundry products with Dell Tech’s expert testing services, tailored for U.S. and Canadian standards.

Our ASTM D4265 testing ensures top performance in stain removal, color fastness, and foaming efficiency. The HCPA’s DCC-11 method evaluates prewash spotters for superior stain removal. Our Dermal Irritection and Corrositex tests guarantee skin safety and prevent corrosive effects.

Achieve excellence and environmental responsibility with Green Seal certifications—GS-48 for household use and GS-51 for industrial applications. Partner with Dell Tech to ensure your products meet regulatory standards and shine in the market.